I live near Tallarook, Central Victoria, Australia, on a heavily wooded property.

My ceramic journey has moved from the early 70’s student years of the Australian Japanese/European/West Coast US funk aesthetic, colourful mid fired tableware of the 80s and 90’s including obsessive decal detail, then to a period of handmade simple porcelain vessels decorated in elemental oxide motifs, to my current phase, with its focus on wood-firing.

Since 2002 I have worked with a group of traditional Rajasthani potters. www.crosshatched123.com.au for more details

In 2012 the connections with the Rajasthani potters lead to a three month Asialink residency in India. Under the tutoring of these potters, a new way of making on the pottery wheel contributed to a loosening aesthetic of my thrown forms. This residency has also been pivotal to my current phase as it was the catalyst for building a wood firing kiln.

The initial years of working with this kiln have seen me return to the classic oriental glazes of my student days and simple functional tableware. Concurrently I investigate the possibilities provided by the vast range of commercial clay available and combination and locally found earth materials.

Recently I have been investigating once fired glazed functional ware, aka raw glazing. I have always included many raw glazed pieces in the firings where glaze functionality was not critical ie planters and sculptural forms, however, I had not been happy with early testing of my usual glazes on bowls. Sophie Harle re ignited this interest with the suggestion of a series of testing, she took on the research and making of the possible suitable glazes. Each glaze was tested on 3 different clays.

There were so many great looking glazes. We narrowed the options. Below are my choices. I tested these on the 2 clays I most frequently use for tableware.

In my last firing, other than teapots and some very fine rimmed cups all was raw glazed. I have found the glazes I have been using, although applied a little thicker have all have worked well. My apprehension was finer pieces with handles, as you can see from the images below, success.

I don’t glaze the outside of plates and bowls, (although I do wax the rims to make a neat interior edge), in time a pattern of glaze volume and action evolves giving a consistent glaze cover. The rest is left to the fire.

Other than teapots and some small fine rimmed cups all pieces in the last firing were raw glazed. It is satisfying to cut out bisque firing, saving both my energy and the planets.

I will use some of the new glazes now included in my glaze book.

Next firing, will be the 70th. Every firing adds to the knowledge of using this kiln and exciting to have some new glazes to explore.

Following are pieces from recent firings.

The following pinchpots were made over summer. My home studio is cooler space for working in hot weather than the grid connected studio where I have my wheel and small electric kiln for bisque firing. The change of pace of making, a return to ‘pinching’ and the opportunity to explore different clays is an appreciated time

The form for this teacup has come to me via the chai cups of the kulhaar potters of India. I have watched these vessels formed in a few movements, deftly taken from the top of the mass of turning clay, placed on the ground, dried, fired and used once.

The unglazed outer was at the suggestion of Bree from Mr Kitly. Until then I had always glazed the top edge of cups to create a soft connection between lip and vessel. I now know this is not necessary when using a fine clay. I do glaze the inside of vessels made for use to ensure easy cleaning. The final say is flashing from the firing.

This teacup appeared in the Garland Magazine Taste makers online vessel exhibition https://garlandmag.com/article/taste-makers-a-selection/

A view inside the kiln as it cools. Its always a temptation to rush to unpack. I unpack reverse of packing taking notes on outcomes of glaze and clay combinations and location in the kiln. This years making has been dominated by a ‘fitout’ for a big family holiday house. The cups in the following image are part of this collection. This glaze combination varied throughout the kiln depending on location, ie heat and ash and flashing impact.

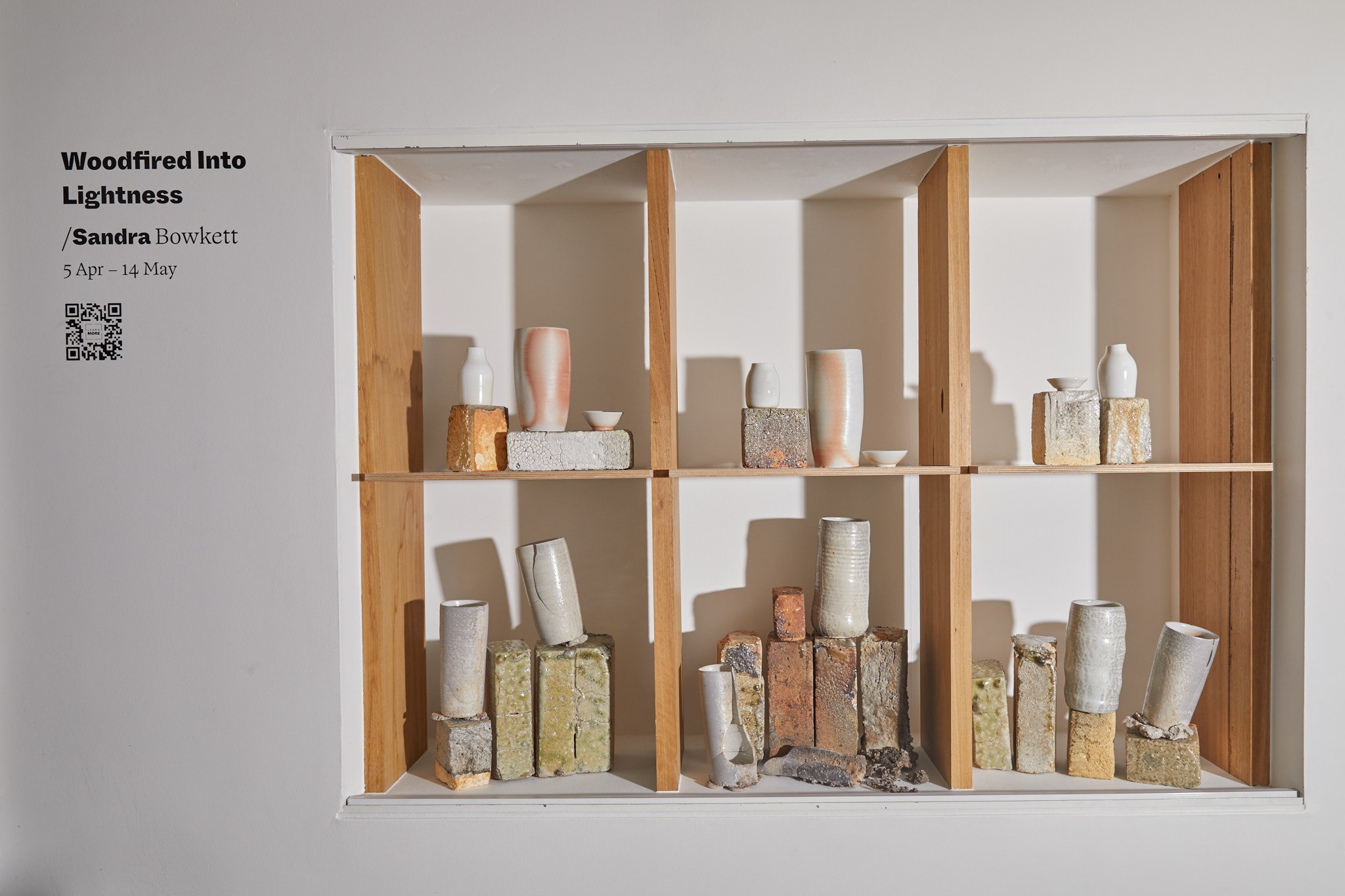

Since having the woodfiring kiln I have been watching the internal bricks change over time both in colour and texture, those close to the fire becoming glazed from the wood ash. I have had to replace some bricks and have been entranced by the quality of their surfaces, some dripping with luscious green ash glaze. I then looked at my pile of broken and used firebricks differently. The form is complete. I have been playing with multiple layering of glazes. I am guided by the composition of colour and texture of the parent brick all of which have a history in other kilns before mine. If I am not satisfied with the outcome it can go in the kiln again for another scorching time.

This has culminated in Woodfired into Lightness in the Vitrine at CRAFT Watson Place Melbourne

Following is the artist statement I have written to accompany the exhibition.

In maintaining my woodfired kiln, bricks have been replaced. These salvaged bricks, often broken in the removal process began to interest me. Each brick tells the story of its place in the kiln. The brick that held the firebox arch encrusted with dark pitted metallic like material; arch bricks covered in a grassy green fluid glaze that is molten ash that melts and remelts with each firing to light open textured insulating bricks further from the firebox that have taken on subtle colour changes where exposed to flame. The intensity of temperature and kiln atmosphere are written in the material.

The work tool became an object. I found the variety of textures, colour and the form ratios 9 x 4.5 x 3 inches* appealing.

I began to glaze these bricks to take equal place with the work I usually fire in this kiln. I used existing fired lines to guide the glaze application with the intent of enhancing marks made by the fire, re-glazing and re-firing many often. Forms became related series, transforming into geological cross sections, snowy and shadowy mountain tops in my imagination.

*metric dimensions just don’t work for bricks.

with thanks to Annika Kafcaloudis for the photographs and CRAFT for the opportunity to create the installation of this story.

Twig vessels

https://garlandmag.com/loop/twig-vessels/

for a story about these vessels